Daewoo Diesel Forklifts Austin

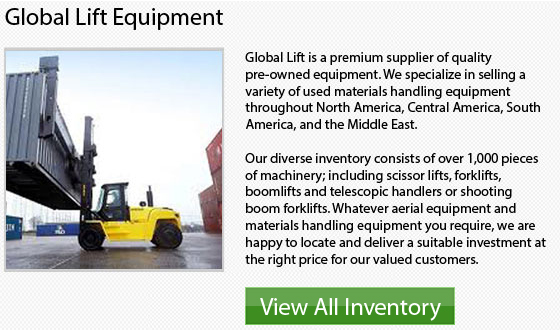

Within the material handling industry, the lift truck has become a key piece of machinery. This equipment is also called a forklift or a powered industrial truck and could carry heavy goods and supplies. These trucks transformed the manufacturing and the warehousing businesses. These days they are used for a wide range of applications and are considered to be essential for material handling.

The forklift needs an operator who uses the control levers to move cargo and materials around the worksite, normally a warehouse or factory. Companies that own their own forklifts have to maintain the machines to ensure they have a long lifespan. Like any equipment parts, lift truck parts, are subject to wear and tear and would become worn over time. In order to make certain the forklift functions safely and efficiently, you must occasionally replace worn or damaged components. Each forklift truck component is made for a particular purpose. Below is a list of several lift truck attachments and their tasks:

Forklift Fork Positioner: The hydraulic attachment referred to as forklift fork positioner helps to position the blades. Tines could move both separately or simultaneously. Without the forklift fork positioner, the operator of the lift truck has to adjust forklift forks by hand for various sizes of loads.

Side Shifter: The side shifter is a hydraulic attachment that allows the forklift operator to laterally shift both the forklift forks and the backrest. This specific attachment makes it easier to place the cargo without having to change the truck's position.

Pole Attachments: Pole attachments are long metal poles used particularly to lift carpet rolls. The poles work better for this purpose compared to forklift forks.

Telescopic Forklift Forks: Telescoping tines are hydraulic attachments that enable the operator to both load and unload from one side. The telescoping forks could handle two pallets of different sizes at the same time. This specific attachment is great for handling pallets in 'double deep racking'.

- Nissan Double Reach Forklifts Austin

Narrow aisle trucks or reach trucks have become more common due to their ability to lessen their aisle count and floor space needs. These types of machinery have a trade-off; the need is for highly... More - Genie Aerial Lifts Austin

The Genie AWP Super Series aerial work platforms are a top favorite in the business because of their ease of use, flexibility and convenience. Their tough design and lightweight maneuverability make them an extremely versatile... More - Caterpillar High Capacity Forklifts Austin

Forklift Motors Purchasing a forklift is not to be taken lightly. A forklift is a big capital expenditure, and a complex machinery with a motor strong enough to perform heavy-lifting jobs. The price tag for... More - Genie Straight Manlifts Austin

The company introduced the innovative, portable pneumatic material lift, the Genie Hoist, at the start of Genie Industries' history in the year 1966. To offer its clients the best, Genie continued to develop fast and... More - Genie Boom Lifts Austin

There are truly many reasons to pick Genie for your lift equipment needs. Genie provides top-of-the-industry items, support, and service to help you with all of your equipment needs. Genie is committed to making your... More