Nissan Counterbalance Forklifts Austin

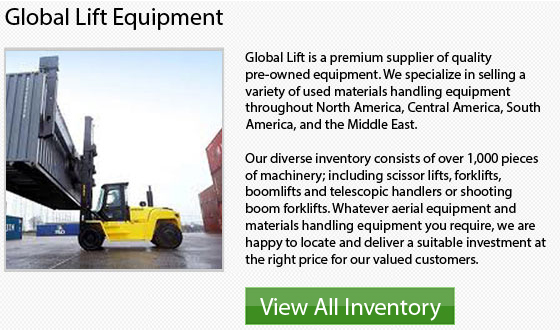

Counterbalance lift trucks are essentially lift trucks that are engineered with counterweight at the back of the equipment. The counterweight works to balance the weight that the forks are carrying at the front of the load. This specific design is engineered to stabilize traditional forklifts. When it comes to electric counterbalance lift trucks, the counterweight is formed by the battery itself.

Counterbalance lift trucks could usually be found in every manufacturer's product range. They are normally manufactured in a range of sizes and configurations, utilizing a variety of fuel sources. These lift trucks could with pneumatic or solid tires, and be designed with 3 or 4 wheels. They are capable of working in various applications. These kinds of lift trucks are outfitted with a variety of accessories. Common attachments and options include: side shifts, hydraulic clamps, slip sheet attachments and fork shifts just to name some items.

Counterbalance lift trucks have revolutionized the material handling business. They have become the cornerstone of storage and distribution systems where they perform stacking, loading, unloading and horizontal transport functions. The average warehouse forklifts are usually used for lift heights less than 20 feet or 6 meters. There have been some recently designed models which are capable of lifting to heights 9.5 meters or 31 feet. The smaller 4000 pound or 1-1.8 ton forklifts are the main workhorses within the majority of warehouses. These are the most common models which most small businesses would own. The typical warehouse counterbalance forklift is a wide-aisle truck that requires around 3 meters or 11 feet to turn in.

Additionally, the counterbalanced forklift is not necessarily confined to warehouse settings. They are usually used for heavy use and container carrying together with pretty much every use in between. Counterbalance lift trucks are the most widely used and versatile of all materials handling machines.

The counterbalanced lift truck is common in numerous working environments, such as production, retail and warehousing. This is because of their versatility and durability. Some of the industrial use comprise: timber, automotive, food and chemical industries.

- Caterpillar Container Handlers Austin

A full container handler which is unequaled in efficiency and lifting capacity is referred to as a Caterpillar Container Handler. Modern technology, high performance and stability combine to make Caterpillar Container handlers the best choice... More - Jungheinrich End Control Forklifts Austin

The lift truck is a vital machinery to help workers lift and move heavy weight supplies and products with speed and efficiency without straining their bodies. The way a company uses this machinery could considerably... More - Snorkel Articulated Boom Lift Austin

A-Series Articulating Boom Lifts The A-Series of articulating boom lifts by Snorkel dominate on the tougher job sites. These equipment combine remarkable maneuverability with precision and power. These machines are capable of reaching working heights... More - Genie Straight Manlifts Austin

The company introduced the innovative, portable pneumatic material lift, the Genie Hoist, at the start of Genie Industries' history in the year 1966. To offer its clients the best, Genie continued to develop fast and... More - Genie Boom Lifts Austin

There are truly many reasons to pick Genie for your lift equipment needs. Genie provides top-of-the-industry items, support, and service to help you with all of your equipment needs. Genie is committed to making your... More