Jungheinrich Dual Fuel Forklift Austin

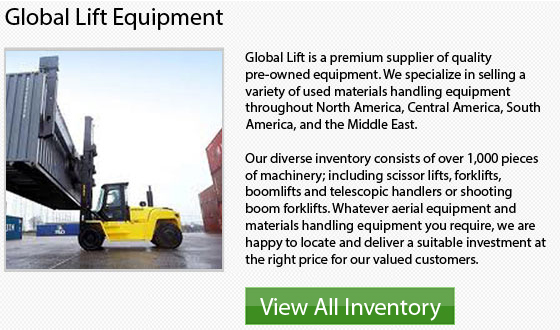

Important equipment used on construction locations comprise vehicles like the lift truck, the bulldozer and the bobcat. Lift trucks could range from very huge to fairly small models. They are made to raise loads and transport products and materials in warehouse or retail settings. Many are designed to easily maneuver in narrow, confined areas. It takes ability and training to master a lift truck.

Lift trucks could be found in most factories because they are important pieces of machines used for efficient materials handling. They are commonly used in stockrooms and warehouses to place and retrieve big or heavy objects which are stored up high. They are important for productivity in work environments where there is a huge range of stock and a small area to keep it in. These kinds of trucks are made to transport huge pallets around in warehouses.

Lift truck drivers in North America are required by law to go through a training and certification course. This training could be done on the jobsite or in a schoolroom or lecture style setting. Normally training is offered at the workplace. Training and accreditation often means a raise for the person acquiring new skills. Forklifts have standard operating measures, that makes it easy to get trained on a array of units.

Smaller equipment accommodate one operator inside the cab and can maneuver in small, tight areas. The bigger machinery are huge and could carry trucks, cars or other kinds of of machines. Forklifts can easily raise thousands of pounds.

Construction companies normally give pay increases to employees who go through the training. Employers will usually send an employee to classes to train on a huge piece of machine. Eagerness to train on a lift truck, a bobcat or a bull dozer will definitely pay off.

- Caterpillar Container Handlers Austin

A full container handler which is unequaled in efficiency and lifting capacity is referred to as a Caterpillar Container Handler. Modern technology, high performance and stability combine to make Caterpillar Container handlers the best choice... More - Jungheinrich End Control Forklifts Austin

The lift truck is a vital machinery to help workers lift and move heavy weight supplies and products with speed and efficiency without straining their bodies. The way a company uses this machinery could considerably... More - Snorkel Articulated Boom Lift Austin

A-Series Articulating Boom Lifts The A-Series of articulating boom lifts by Snorkel dominate on the tougher job sites. These equipment combine remarkable maneuverability with precision and power. These machines are capable of reaching working heights... More - Genie Straight Manlifts Austin

The company introduced the innovative, portable pneumatic material lift, the Genie Hoist, at the start of Genie Industries' history in the year 1966. To offer its clients the best, Genie continued to develop fast and... More - Genie Boom Lifts Austin

There are truly many reasons to pick Genie for your lift equipment needs. Genie provides top-of-the-industry items, support, and service to help you with all of your equipment needs. Genie is committed to making your... More